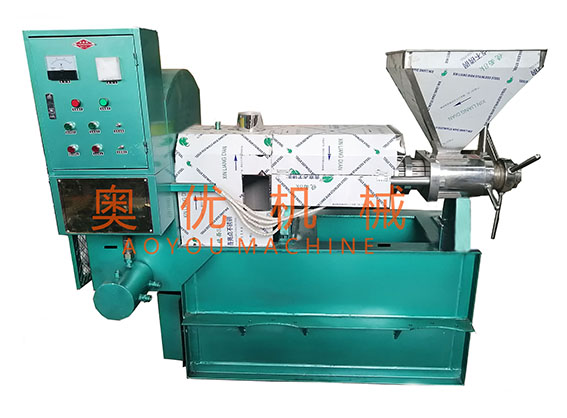

Rapeseed oil press

Energy conservation, emission reduction, and harmonious life! Aoyou has been committed to technology research and development and product building in the Oil crop processing of agricultural and sideline products field since its establishment, and has accumulated to provide high standard [Rapeseed oil press] products for many customers!

The rapeseed oil press produced by Aoyou Machinery and Equipment Co., Ltd. - Aoyou Machinery also has many functions such as automatic control heating, oil extraction, filtration, etc. It can heat the pressure chamber of the rapeseed oil press before pressing, improve the oil yield, and filter the crude oil in time during the pressing process. Can be pressed: rapeseed, cottonseed, soybean, peanut, flaxseed, palm, castor, Su seed, sesame, sunflower seed, rice bran, corn germ, walnut, almond, evening primrose, tea seed, pine seed, white soil and other oil crops. The advantage of rapeseed oil press is that the single machine uses very little electricity and covers only a few square meters, realizing the automation of production.

The rapeseed oil press produced by Aoyou Machinery Co., Ltd. and the small spiral rapeseed oil press also have the functions of automatic control heating, oil extraction, filtration and other functions. It can heat up the pressure chamber of the rapeseed oil press before pressing, improve the oil yield, and filter the crude oil in time during the pressing process. Can be pressed: rapeseed, cottonseed, soybean, peanut, flaxseed, palm, castor, Su seed, sesame, sunflower seed, rice bran, corn germ, walnut, almond, evening primrose, tea seed, pine seed, white soil and other oil crops. The advantage of rapeseed oil press is that the single machine uses very little electricity and covers only a few square meters, realizing the automation of production.

The new rapeseed oil press equipment can save energy and reduce consumption, prolong the service life of the oil press, make the oil squeezed by the oil press bright, without sediment and smoke, and meet the national edible oil standards, so that consumers can eat at ease. Aoyou Machinery and Equipment Co., Ltd. - Compared with similar products, the new rapeseed oil press produced by Aoyou Machinery has good comprehensiveness, high reliability and strong wear resistance. Now, the oil press produced by our factory has spread all over the country, relying on more users to make publicity. I believe that the eyes of the masses are bright, and the oil press equipment of our factory will be the choice of friends.

Characteristics of rapeseed oil press produced by Aoyou Machinery and Equipment Co., Ltd. - Aoyou Machinery:

1. High oil yield: the oil yield is increased by 10-30% by adopting directional pressure bearing, multistage propulsion, and one-time squeezing;

2. Large production capacity: strengthen the feeding system, increase the speed of promotion, and improve the work efficiency by more than 30%;

3. Automatic control: automatically control the pressing temperature;

4. Built-in vacuum diverter to effectively separate oil and slag* Convenience: exquisite structure, less space occupation;

5. Fully enclosed protection, easy to operate; Durable: the fuselage is made of excellent wear-resistant steel and anti-fatigue casting, with stable performance and can work continuously for a long time; The machine watch is made by electrostatic spraying of very new materials, with strong adhesion, oil resistance, high temperature resistance, beautiful and generous, and clean and sanitary.

6. Actual benefit analysis: each machine can process more than 1 ton of peanuts per day (10 hours), and more than 300 jin of peanut oil per thousand jin, worth more than 3500 yuan. 700 jin of pressed peanuts, worth 2400 yuan. The purchase of peanuts is about 4500 yuan per 1000 jin, the gross profit of production and processing of peanuts is more than 1000 yuan, and the monthly profit is about 30000 yuan. If the pressed peanuts are further processed, the benefits will be more considerable.

Principle of rapeseed oil press produced by Aoyou Machinery Co., Ltd. - Aoyou Machinery

When the rapeseed oil press is running, the processed oil enters the press chamber from the hopper. The material embryo is continuously pushed inwards from the press screw to press. Because the material embryo is in motion in the chamber of rapeseed oil press, under the high pressure of the chamber, there is a great friction resistance between the material embryo and the screw press, and between the material embryo and the chamber, which can cause friction between the material embryo and the micro-material, resulting in relative movement. On the other hand, because the diameter of the root circle of the screw is gradually thickened and the pitch is gradually reduced, when the screw is rotated, the thread can force the material embryo to move forward and turn outward. At the same time, the material layer close to the surface of the screw thread also rotates with the screw shaft. In this way, each embryo particle in the crushing chamber does not move at the same speed and in the same direction, but there is also relative movement between particles. The heat generated by friction also meets the heat required for the operation of the oil pressing process, which helps to promote the thermal denaturation of the protein in the feed embryo, destroy the colloid, increase the plasticity, and reduce some viscosity, which is easy to precipitate oil, thus improving the oil yield of the oil press, so that the oil pressure in the oil is squeezed out, and flows out from the circular and strip gaps.

Technical parameters of rapeseed oil press and small spiral rapeseed oil press produced by Aoyou Machinery Co., Ltd. - Aoyou Machinery:

| Oil press model | Type 70 | Type 100 | Type 125 | |

|---|---|---|---|---|

| Screw diameter | 70mm | 100mm | 125mm | |

| Screw pressing speed | 37r/min | 38r/min | ||

| Diameter of inner circle of blast chamber | 102mm | 128mm | ||

| Power supply | Host | 3kw | 7.5kw | 15kw |

| Vacuum pump | 0.75kw | 1.1kw | 2.2kw | |

| Heater | 2.2kw | 2.4kw | 3kw | |

| Yield | 45-70kg | 150-200kg/h | 300-400kg/h | |

| Operating Weight | 320kg | 1100kg | 1500kg | |

| Overall dimension | 1450x870x1180mm | 1800x1200x1500mm | 2300x1300x2200mm | |

There are many kinds of oil press machinery, and different performance, raw materials and output are different. With the continuous improvement of people's dietary standards, the requirements for edible oil have not been improved, and the rapeseed oil press has become a good choice for many people. The intelligent pressing of edible oil is changed on the basis of the oil press, and its function is more perfect. Not only for the processing and operation of various raw materials, the edible oil produced is healthy and delicious, and is deeply loved by friends.

Operation instructions and maintenance of rapeseed oil press produced by Aoyou Machinery Co., Ltd. - Aoyou Machinery

instructions

1. Before use, read the operation manual carefully and be familiar with the performance characteristics and operation methods of this machine.

2. Before starting the machine, a check must be carried out to ensure that all fasteners are not loose, the handle rotates flexibly, and the pulley is turned by hand. All running parts should be normal without abnormal noise. Then fill the reducer with 30 # engine oil.

3. Loosen the lock nut, turn the adjusting screw counterclockwise, (the adjusting handle rotates counterclockwise, the cake gap narrows, and the adjusting handle rotates clockwise, the cake gap widens) so that the cone of the screw press is against the cone of the cake ring, and then turn out the adjusting screw clockwise (3-5 turns), and then tighten the nut to prepare for starting.

4. The machine is connected to three-phase four-wire power supply. After the power supply is connected, the main shaft should rotate counterclockwise. In any case, the machine must have a good grounding device, otherwise it cannot be started.

5. Adjust the temperature controller (2) to the required temperature of 120 ℃ - 180 ℃ (depending on the oil). Turn the heating switch to the heating position of the main machine to heat the machine. At this time, the green light on the temperature controller is on and the red light is off. When the machine temperature rises to the set temperature, the red light is on and the green light is off. The machine temperature is automatically controlled and maintained at the set temperature. When the temperature is low in winter, turn the heating switch to all the heating positions of the main machine, Increase the temperature of the oil pan to facilitate the retention of oil.

6. Press the main motor button, (turn the main switch to the positive position) the main engine starts to run, and the rotation direction should be counterclockwise.

7. After the installation of the new oil press, grind and press it for 4 to 8 hours. The method is to slowly feed the dried oil cake from the hopper and repeatedly press it back to make the press chamber smooth. Remember not to directly pour the material into the hopper at the beginning of grinding, but to grasp and feed it by hand to prevent the press screw shaft from getting stuck. If the feeding is too strong, there is abnormal noise in the pressing chamber or the pressing screw shaft is jammed, stop the machine immediately to remove the obstruction, or start the grinding after reassembly. It is strictly prohibited to tow by force.

8. During normal oil extraction, the feed must be kept uniform, not too much or too little, or the material should be broken and idle. At this time, the load of the machine is normal, the operation is stable, and the sound is rhythmic. The cake is smooth, the low pressure section is basically free of slag, and the high pressure section has a small amount of oil slag, but the proportion of slag in the oil is not more than 10%. The temperature in the pressing chamber can reach 150-200 ℃. The green smoke from the cake outlet should be discharged through the hood through the smoke pipe. The hot cakes should be spread out in time, and should not be piled up or shipped in a hurry, otherwise natural phenomena will occur. When the continuous working time is long and the machine temperature is too high, cooling measures such as electric fan blowing shall be taken.

9. When the pressed oil flows into the oil filter, press the vacuum pump button, the vacuum pump starts to operate, the air in the oil filter is pumped out, the internal pressure is formed in the oil filter barrel, the oil above is naturally pumped into the oil filter, and the oil residue is isolated on the filter cloth. After the pressing is completed and the oil is pumped, open the valve on the oil filter, stop the vacuum pump operation, and the dry residue is formed on the filter cloth, which is scraped off with a scraper, Then the valve at the bottom of the pure oil filter in the oil filter can be discharged.

Work hard to create Aoyou national brand! The century-old journey has laid a solid foundation for thought.Thank you for your attention to the Rapeseed oil press product information on the China Aoyou Cooking oil equipment website, and welcome your valuable suggestions to jointly promote the international competitiveness of Made in China!